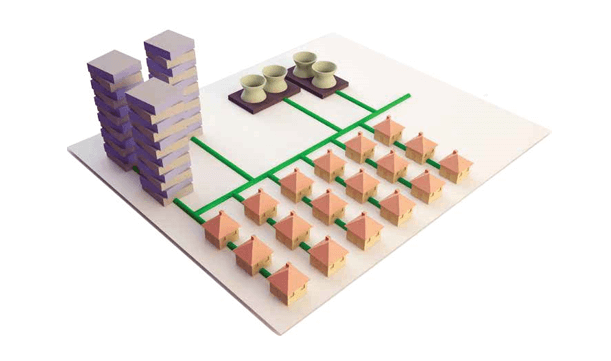

In district heating & cooling systems, it is of critical importance to determine the location of possible leaks and to intervene in the operation of systems that provide constant service to more than thousands of subscribers. Since the pre-insulated pipes used in these systems are buried directly underground, leakage detection systems may be needed for constantly controlling the system and determining its location it in case of leakage.

Basically, the leakage detection system consists of digital equipment for constant control of the pipeline and reporting its location to the system to which it is connected in case of leakage. Depending on the heating or cooling purpose the project, in which pre-insulated pipes are used, the equipment to be used in the leakage detection system varies according to the operating conditions anticipated. In this chapter, the components of the leakage detection system and their correct selection according to the operating conditions are explained.

DETECTION OF LEAKAGE OCCURRENCE WITH RESISTANCE AND IMPEDANCE MEASUREMENT

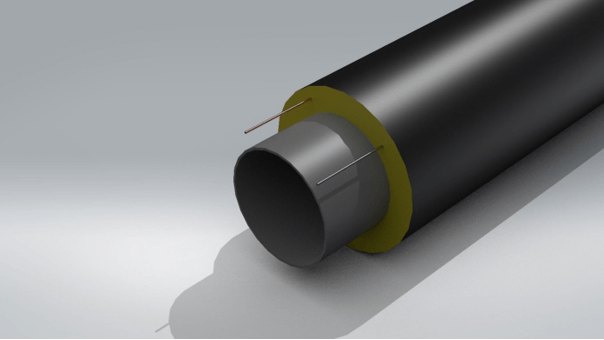

For the leakage detection system, cabling is made in accordance with the system to be used in the insulation of Yalçın Boru branded pre-insulated pipes. During the field installation of the pipes, the connection of the cables in insulation and the detectors to be placed at the locations deemed appropriate by Yalçın Boru Project Department for the system must be done.

For district heating systems, two wires – one of copper and one of tin-plated copper – with a cross-sectional area of 1.5 mm², are placed in insulation during pipe manufacturing. The wires are placed along the pipe in insulation by keeping a certain distance from the carrier pipe. At the end of manufacturing of each pipe, the conductivity of the wires is checked. It is suitable for both resistance measurement and impedance measurement method.

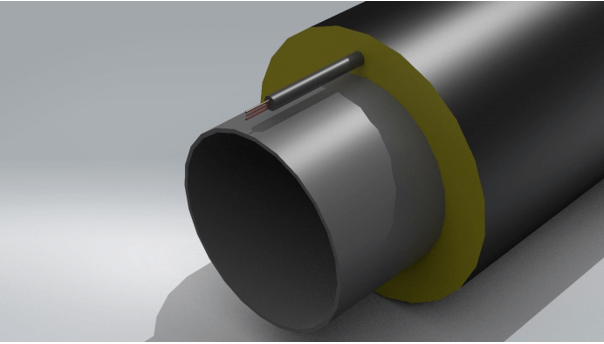

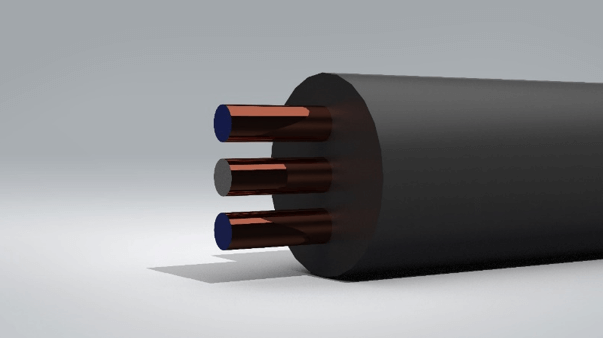

On the other hand, in district cooling systems and in district heating systems with plastic-based carrier pipes, it is suitable to place three 3DC cables, each with a 0.75 mm² cross-sectional area, consisting of copper wires gathered and insulated and made one single cable, inside insulation during pipe manufacturing.

Of these fully insulated wires, the one in the middle (white) functions as a reference cable, while the wires (blue) on the two outer wings function as an alarm cable with impedance measurement.

In district cooling systems, a low amount of moisture may occur inside the insulation. Due to this issue and especially due to situations such as the repair of the line during operation, problems may occur in the leakage detection system as a result of operations such as cutting/re-insulation. In order to prevent this issue, 3DC cables that can operate properly in spite of the formation of moisture must be used in district cooling or district heating systems where plastic-based pipes are used.

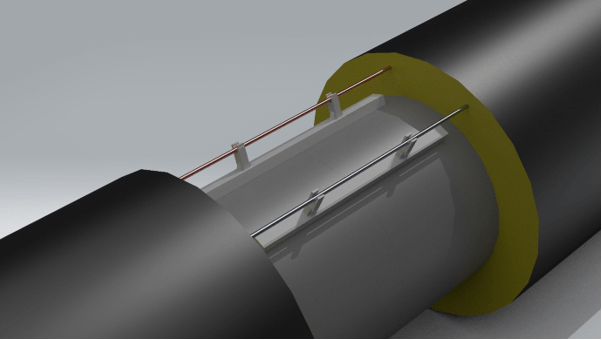

During the field installation of the wires, as can be seen with the image below, installation must be made by means of the bridges supplied with the joint insulation kit, in a way that prevents contact with the carrier pipe.

DETECTION OF THE LOCATION OF LEAKAGE AND DETECTOR TYPES

According to the operating conditions of the pipeline system and the type of use of the leakage detection system, different detector types are offered to our customers under the brand of Yalçın Boru.

First of all, it is necessary to decide whether the system will be passive or active.

In passive systems, the detectors are not connected on the line. For measuring, there are connectors on the pipeline at certain intervals. During operation, in case of a suspicion of leakage, it may be possible to detect the leakage by making an on-site measurement with a portable detector provided by Yalçın Boru.

In active systems on the other hand, detectors are connected on the pipeline, instant data obtained from these detectors and the system are constantly monitored via computer software, and the system automatically gives an alarm in case of leakage.

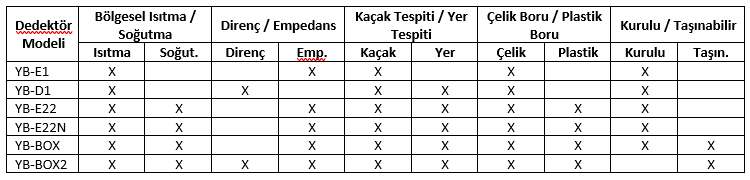

The points to be considered in the detector type to be selected for the system are as follows:

An example detector photo is as follows:

Our detector models are designed in alternatives that can operate in both resistance measurement based systems and impedance measurement based systems and detect the leakage location. In addition, bag-type sets developed for field operations, including industrial tablets, detectors and measuring devices, are also included in the product range of Yalçın Pipe Leakage Detection Systems.

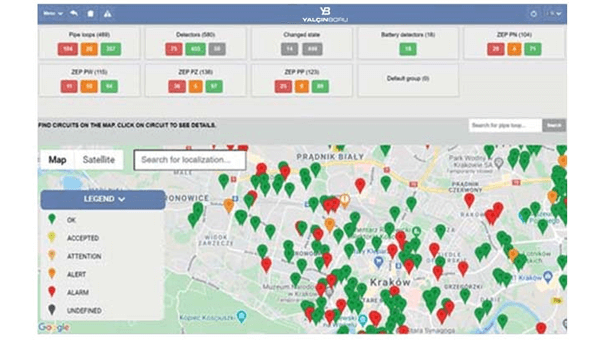

The detectors can provide instant data flow to the software of the system via GSM, LAN or MODBUS, and allow the operators to have full control of the system. Leakage location, system logs and instant operating status can be controlled through our completely free software.

You can contact Yalçın Boru for the selection of detector types suitable for your project in leakage detection system, their positioning on the pipeline, supervisory services and all other issues.