How is District Heating Done?

What is district heating?

A district heating system is the heating of many buildings from a power plant or a cogeneration plant where electricity and heat energy are produced together or from another heat source such as geothermal or industrial wastewater and providing hot water requirements. In the district heating system, the heat generated from multiple energy sources is delivered to the users with a pre-insulated (geothermal) pipe. With the large-scale heat distribution system, the heating and hot water requirements of industrial facilities, mass housing structures, neighborhoods, and city-like places are met. The heat network consisting of insulated pipes distributes the heat received from a central source to residential or non-residential buildings.

Nowadays, energy demands have increased with the increasing population, urbanization, and housing. Natural gas is a leading energy source to meet energy demands. However, since we are mostly foreign-dependent in natural gas and due to the supply security problem, energy efficiency has become important in terms of production.

The productivity of combined cycle power plants installed in accordance with new technologies has increased up to approximately 60%. Even in power plants with the highest level of productivity in terms of electricity, there is a potential that can be utilized as waste heat. This potential heat can make a great contribution to energy saving.

District heating systems help to reduce carbon emissions and lower electricity and heating bills for both domestic and non-domestic users. As district heating systems expand and interconnect, energy efficiency improves and the potential for carbon savings increases.

What are the factors affecting the use of district heating?

- There are many factors affecting the use of district heating systems. These factors can be listed as follows.

- Improvement and protection of air quality

- Environmental constraints

- Suitability of the area where the system will be applied for pipe laying

- Distance and proximity of heat distribution locations to each other

- Availability of access to other alternative energy sources

- The laws in force do not contain unfavorable regulations on district heating

- City plans

- Costs

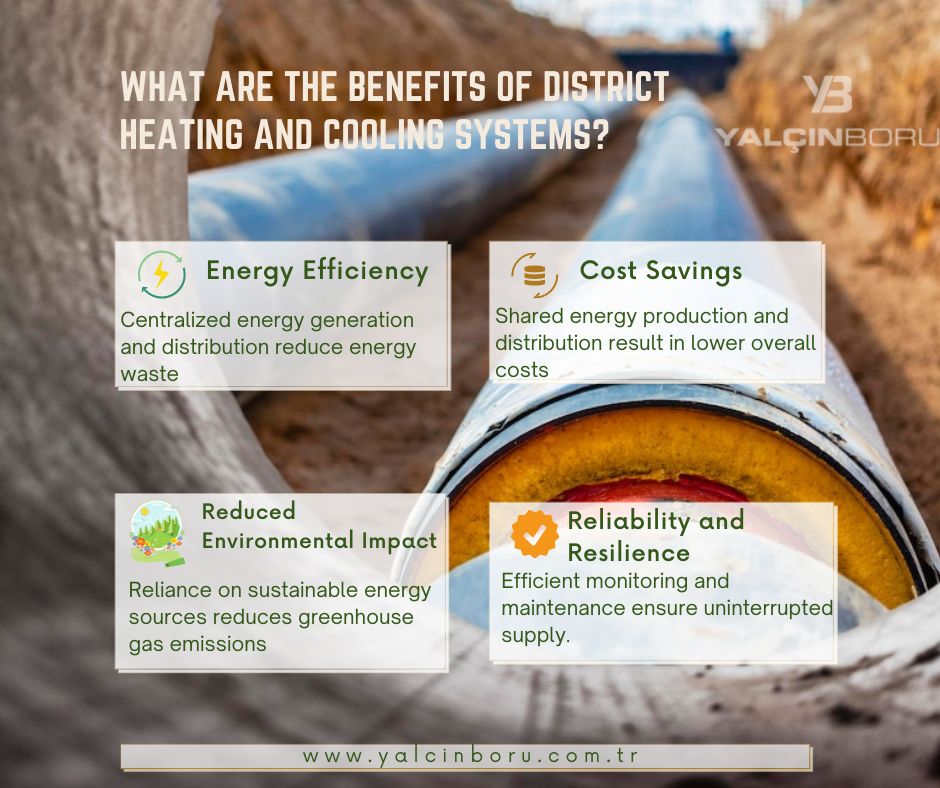

What are the benefits of district heating and cooling systems?

- Reduces air pollution.

- Reduces the level of harmful carbon dioxide emissions.

- Increases energy security.

- It makes it possible to utilize the heat in the idle position (this is an application with higher efficiency).

- The use of renewable energy is made visible.

- In the district heating method, hot water, steam or chilled water produced in a central facility is transported to the users through pre-insulated (geothermal) pipes underground. Thus, the problem is solved with district energy systems without the need for their own boilers, furnaces, coolers, air conditioners and other heating systems in homes or out-of-home places.

Should steel or polymer pipes be preferred for district heating?

Regardless of the size of the district heating network plan, it is very important to what kind of pre-insulated (geothermal) pipe to choose. The first modern glued-pre-insulated pipe systems started to appear in the world around 1970 years. In the first period, the pipes consisted of a steel and rigid pipe coated with glued polyurethane foam and wrapped with an outer sheath of high-density polyethylene. In the second half of the 20th century, when thermoplastic technology started to develop, different products started to enter the system. These products are service pipes, which are not subject to corrosion in a short time, can be rolled and are more flexible than traditional steel systems. Today, both systems continue to be strengthened.

How are polymer pipes stronger than metals?

If you have a plumbing system that you need to have built, replaced or renewed, it is very important to choose the most suitable pipe system for the process. Recently, metal is not preferred due to the advantages of plastic. Metal pipes are replaced with polymer pipes. Polymer pipes, also known as PVC pipes, are stronger and more popular than metal pipes. Polymer pipes are usually made of polyvinyl chloride (PVC), a combination of plastic and vinyl. CPVC (chlorinated polyvinyl chloride) pipes, PE-RT pipes (elevated temperature polyethylene) are also among your options. Polymer pipes are safe, robust, durable, low-cost, recyclable pipes. For this reason, polymer pipes have become used in many areas such as drinking water transport, drainage systems and fire sprinkler solutions.

Advantages of using plastic (polymer) pipes over metal pipes

- Plastic, which can be bent and easily shaped, has become a valuable raw material in the pipe industry with its other properties.

- Since polymer pipes are not affected by corrosion, there is no bacterial formation. Thanks to this feature, it provides safe, clean, and healthy drinking water transport. While the accident and injury rate is high in the manufacture of metal parts, the production stage is also safer because the polymer pipe is soft and smooth.

- Generally, the life of underground polymer pipes can exceed 100 years. This is due to the strength of plastic to resist physical, chemical, environmental, and weather attacks. Metals, on the other hand, cannot protect themselves from the negative effects of chemical attacks and weather events.

- The cost of PVC pipes remains very low compared to other pipes. The cost efficiency of polymer pipes is high. Purchase fees, installation and maintenance fee, and operating costs are more favorable than metal pipes. This feature causes it to be preferred by homeowners and industrialists.

- Polymer pipes (plastic) are lighter than their metal counterparts, but ten times lighter than steel pipes. In industry, the lightness of the part is a very important feature. Steel pipes are difficult and costly to replace due to their heavy weight.

- Polymer pipes, which are environmentally friendly, have many positive environmental aspects since they are plastic with low carbon content. Since energy consumption is low when producing polymer pipes, energy efficiency is high. Non-toxicity is another feature that proves that it is environmentally friendly. Since water leakage is high in metal pipes, it causes water bills to increase. Since water leakage will be less in polymer pipes, it also contributes to the saving of water.

- While plastic can be recycled, metals cannot be recycled. Recyclability is one of the biggest advantages of plastic. If the metal pipe is damaged, it is discarded and replaced with a new one. Plastic pipes can be melted several times and reused.

- Production of plastic pipes is more serial and easy. The short production cycle also reduces the cost.

Which system should be chosen, polymer or metal?

- The non-corrosive properties of polymer pipes make them superior, but depending on the size and complexity of the district heating (DH) network, you may need to use both polymer and steel pipes. The decisive factors in deciding which system to use are temperature levels and pressure.

- Applications with transport pipes made of polymers, such as PP-R and PEX, can be used without any problems at continuous operating temperatures of up to 95 °C. However, service life will not last long at this temperature. At lower temperatures, the service life will be better.

- Steel pre-insulated (geothermal) pipes are able to cope with constant operating temperatures of 120 °C and above. While the diameter range of steel pipes is widely available from DN20 mm to 1,200 mm, the range of diameters available in polymer systems is more limited. PPR based polymer pipes have an age range up to approximately DN300 mm.

- For very large district heating systems, a hybrid system is often used, with steel systems forming the arterial heart of the distribution network and flexible plastic systems for making smaller connections.

- For smaller jobs, where narrower trenches are required, polymer pipes can be rolled and delivered to the job site in order to be able to curve around obstacles when they are present. The installation speed of this flexible system is very high. Therefore, on-site disruption is both low and short-lived.

- There is no need to keep trenches open in very large sizes to perform welding, NDT or hydraulic pressure tests. There is no need to keep trenches open in large quantities. Polymer pipe systems in larger sizes lose their flexibility. 12-metre length polymer pipes are considered more suitable.

- Polymers minimize heat loss due to their low conductivity. This reduces costs in terms of energy and emissions. Friction losses are also more advantageous than other alternatives.

- Many factors are effective when choosing regional thermal insulation systems. Steel pre-insulated (geothermal) pipes will exist as they develop in accordance with technology and continue to increase their place in the low-carbon heat revolution. Polymer pipes also continue to gain market in district heating systems.

CONTENTS

- What is district heating?

- What are the factors affecting the use of district heating

- What are the benefits of district heating and cooling systems?

- Should steel or polymer pipes be preferred for district heating?

- How are polymer pipes stronger than metals?

- Advantages of using plastic (polymer) pipes over metal pipes

- Which system should be chosen, polymer or metal?