Pre-Insulated (Thermal Insulated) Galvanized Steel Pipes - Geothermal Pipe - Technical Specifications

You can find the manufacturing standard and galvanising standards of galvanised pipes in the table below.

Technical Specifications

|

PRODUCTION STANDARDSI |

QUALITY OF STEEL |

|

TS EN 10255+A1 |

S195T |

|

TS 11348 EN 10240 |

|

|

TS EN 1461 |

|

|

DIN 244 |

|

|

ASTM A90 |

|

Rigid polyurethane foam is an insulation material with extremely low thermal transmission coefficient, consisting of mixing of polyol and isocyanate in certain ratios and pressure injection of these materials. PUR, which is injected between the carrier pipe and the casing pipe (HDPE), provides heat insulation as well as enabling two pipes operating as one pipe by bonding them together, and filling in the space between the pipes longitudinally. In the manufacturing of pre-insulated pipes, the PUR in accordance with the standard TS EN 253 has to meet the following minimum requirements:

Technical Specifications

|

Components |

Polyol and Isocyanate |

|

Minimum cellular mass density |

55 kg/m3 ISO 845 |

|

Max. Thermal Conductivity Coefficient |

0,029 W/mK ISO 8497 |

|

Average cell structure |

< 0,5 mm |

|

Closed cell content |

> %88 ISO 4590 |

|

Min. Radial Compressive Strength |

0,30 MPa ISO 844 |

|

Water absorption at high temperature |

< 10% when tested according to TS EN 253 5.3.5 |

|

Axial cutting strength |

23 °C ± 2 °C ≥ 0,12 N/mm² |

|

140 °C ± 2 °C ≥ 0,08 N/mm² |

|

|

Temperature range |

-50 °C / +148 °C |

|

Impact strength |

No damage must exist - when tested in accordance with EN 253 5.4.5 |

|

Linear Water Tightness |

Must be Watertight When tested in accordance with EN 253 5.4.6 |

|

Chlorofluorocarbon |

None |

|

Service life of insulation according to continuous service temperature |

3 years at 140 ˚C |

|

30 years at 120 ˚C |

|

|

50 years at 115 ˚C |

Extruded polyethylene casing pipe is used on the outermost part, which protects the insulation material from external factors and chemicals. The HDPE casing pipe manufactured in accordance with the standards TS EN 253 and TS EN 12201-2 must contain antioxidants, UV stabilisers and carbon black.

Technical Specifications

|

Standard |

EN 253, EN 12201-2 |

|

Dimensions |

EN 253 bölüm 4.3.2.2 tablo 5 |

|

Material |

PE 80 – PE 100 ISO 9080 |

|

Density |

> 944 kg/m3 ISO 1133 |

|

Thermal Conductivity Coefficient |

0,43 W/mK |

|

Thermal Stability (OIT) |

> 20 min (210 °C) ISO 11357-6 |

|

Temperature Range |

40 °C / + 80 °C |

|

Cracking resistance under stress |

> 300 hrs(4 MPa, 80 °C) ISO 16770 |

|

Post-thermal treatment changes |

<%3 (no damage must exist) ISO 2505 |

|

Melt Flow Index (MFI 190°C/5kg) |

0,2 < MFR ≤ 1,0 g/10dk ISO 1133 |

|

Carbon black content |

> by mass % 2,5 ± 0,5 ISO 6964 |

|

Carbon black propagation degree |

<3 ISO 18553 |

|

Breaking elongation |

>% 350 ISO 6259-1 |

|

Hydrostatic Strength |

10,8 bar 80°C 165 sa ISO 1167-1-2 |

|

Inner surface treatment |

Corona process on extruded line (on-line) |

|

UV Protection |

Yes |

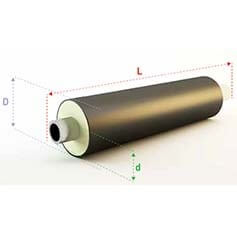

| PRODUCT NOMINAL SIZE | STEEL PIPE | HDPE CASING PIPE | PUR | PIPE LENGTH | INSULATED PIPE WEIGHT(kg/m) | |||||

| DN | INCH | Outer Diameter dₐ (mm) | Wall Thickness t (mm) | Outer DiameterD (mm) | Wall Thicknesss (mm) | Inner Diameter (mm) | Thickness (mm) | L (mt) | ||

| Ø 15/75 | 15 | 1/2" | 21,3 | 2,60 | 75 | 3,0 | 69,0 | 23,85 | 6 | 2,12 |

| Ø 20/90 | 20 | 3/4" | 26,9 | 2,60 | 90 | 3,0 | 84,0 | 28,55 | 6 | 2,74 |

| Ø 25/90 | 25 | 1" | 33,7 | 3,20 | 90 | 3,0 | 84,0 | 25,15 | 6 | 3,56 |

| Ø 32/110 | 32 | 1 1/4" | 42,4 | 3,20 | 110 | 3,0 | 104,0 | 30,8 | 6 | 4,61 |

| Ø 40/110 | 40 | 1 1/2" | 48,3 | 3,20 | 110 | 3,0 | 104,0 | 27,85 | 6 | 5,05 |

| Ø 50/125 | 50 | 2" | 60,3 | 3,60 | 125 | 3,0 | 119,0 | 29,35 | 6 | 6,78 |

| Ø 65/140 | 65 | 2 1/2" | 76,1 | 3,60 | 140 | 3,0 | 134,0 | 28,95 | 6 | 8,42 |

| Ø 80/160 | 80 | 3" | 88,9 | 4,00 | 160 | 3,0 | 154,0 | 32,55 | 6 | 10,76 |

| Ø 100/200 | 100 | 4" | 114,3 | 4,50 | 200 | 3,2 | 193,6 | 39,65 | 6 | 15,60 |

| Ø 125/225 | 125 | 5" | 139,7 | 5,00 | 225 | 3,4 | 218,2 | 39,25 | 6 | 20,64 |

| Ø 150/250 | 150 | 6" | 168,3 | 5,00 | 250 | 3,6 | 242,8 | 37,25 | 6 | 24,74 |

- Non-insulated pipe ends will have a length of 150 - 250 mm ±10 mm.

- Upon request, manufacturing can be made in lengths, diameters and insulation thicknesses different from the values in the table.

- Our company reserves the right to make changes on this and all other data in the brochures, written documentation and on our website. You may contact our company for getting up-to-date information.

Pre-Insulated Galvanized Steel Pipes

What is Galvanized Steel Pipe?

What is Pre-Insulated Galvanized Steel Pipe?

Pre-insulated galvanized pipes produced by Yalçın Boru to these standards are among the most preferred in the industry due to their resistance to external factors, impacts, moisture and all physical conditions.

Advantages of Pre-Insulated Galvanized Steel Pipes

- It offers a very high performance in terms of thermal insulation. Fluid transported at a consistent temperature contributes to energy efficiency. It preserves heat in district heating and cooling systems.

- Zinc coating is one of the most effective materials against corrosion. Zinc used in the coating of pre-insulated galvanized steel pipes creates a protective film on the pipe surface. In this way, it provides the advantage of protection against moisture and other corrosive elements.

- It is extremely resistant to rust.

- It can be used in both outdoor and underground applications.

- Another advantage of geothermal galvanized steel pipes is their long life.

- These pipes are very economical. Since it can be used for a long time, maintenance and replacement costs are low.

- Its usage area is very wide.

- Since the pre-insulation and sheath pipe are integrated into the galvanized steel pipe, it is easy to install and the installation time is short.

Usage Areas of Pre-Insulated Galvanized Steel Pipes

These geothermal pipes have a wide range of uses due to the many advantages they offer. Usage areas of pre-insulated galvanized steel pipes are as follows:

- water distribution networks

- Wastewater and sewage systems

- Natural gas distribution systems

- oil pipelines

- construction projects

- Heating and cooling systems

- maritime activities

- farming areas

What is the Lifespan of Pre-Insulated Galvanized Steel Pipes?

The lifespan of galvanized steel pipes is up to 50 years. When pre-insulation is applied to these pipes, their lifespan may vary depending on the service temperature. Insulation life is as follows according to continuous service temperature: 3 years at 140 ˚C, 30 years at 120 ˚C and 50 years at 115 ˚C.

What are the Prices of Pre-Insulated Galvanized Steel Pipes?

Pre-insulated galvanized steel pipe prices vary depending on various factors such as diameter, thickness and weight of the steel pipe, HDPE sheath pipe and insulation material. You can contact us to get information about current prices and our other products according to the sizes you need.

Pre-insulated galvanized steel pipes have a delicate production process that requires professionalism. Steel pipes need to be galvanized correctly. Afterwards, it should be covered with high quality insulation material and the casing pipe should be mounted on it. Therefore, if you want to use these pipes safely for many years, you should choose a reliable brand. We recommend that you choose geothermal galvanized steel pipes produced by Yalçın Boru, the industry leader with years of experience.

You can also examine our pre-insulated steel pipe, pre-insulated plastic pipe, pre-insulated rockwool reinforced seamless steel pipe and other pipe types to choose the geothermal pipe suitable for your projects.