In our day, energy and the efficient use of energy are among the most important factors, and the main purpose of use of pre-insulated pipes is to keep heat loss at the lowest possible level and obtain the highest efficiency from energy. The calculation method given below can be used for calculating the heat loss theoretically.

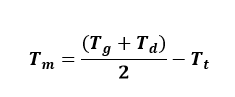

First of all, the average fluid temperature is calculated:

Tm (˚C) : Average temperature of the fluid

Tg (˚C) : Temperature at the direction of flow

Td (˚C) : Temperature at the direction of return

Tt (˚C) : Outdoor air temperature

In order to calculate the total thermal conductivity resistance of the pre-insulated pipe system, firstly the resistances of each layer of the system must be calculated respectively.

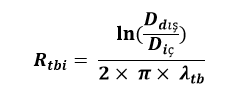

Carrier Pipe Thermal Conductivity Resistance:

Rtbi (m.°C / W) : Thermal conductivity resistance of the carrier pipe

Din (m) : Inner diameter of the carrier pipe

Dout (m) : Outer diameter of the carrier pipe

λtb(W / m.°C) : Carrier pipe thermal conductivity coefficient (Table 1)

|

Type of the Service Pipe |

Thermal Conductivity Coefficient (W/m.˚C) |

|

Black Steel |

76 |

|

Stainless Steel |

16 |

|

PP-R |

0,15 |

|

Copper |

400 |

|

CTP |

0,31 |

|

Polyethylene |

0,43 |

Table 1: Thermal Conductivity Coefficient by Types of Carrier Pipe

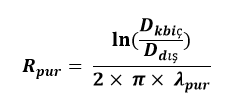

Polyurethane Insulation Thermal Conductivity Resistance:

Rpur= ln(DkbinDout)2× π× λpur

Rpur(m.°C / W) : PUR insulation thermal conductivity resistance

Dkbin(m): Inner diameter of the casing pipe

λpur(W / m.°C): PUR insulation thermal conductivity coefficient (0.026 W / m.°C can be taken)

Thermal Conductivity Resistance of the HDPE Casing Pipe:

Rkb(m.°C / W) : Thermal conductivity resistance of the casing pipe

Dkbout(m): Outer diameter of the casing pipe

Dkbin(m): Outer diameter of the casing pipe

λkb(W / m.°C): Thermal conductivity resistance of the casing pipe

Outdoor Thermal Conductivity Resistance:

- Underground Installation

Rt(m.°C / W) : Thermal conductivity resistance of earth

Z(m) : Filling height of earth

λt(W / m.°C): Thermal conductivity coefficient of earth (Table 2)

|

Type |

Density (kg/m3) |

Volumetric Humidity Rate % |

Thermal Conductivity Coefficient (W/m.˚C) |

|

Sand |

1500 |

4 |

1,04 |

|

1800 |

14 |

1,7 |

|

|

Clay Soil |

1500 |

23 |

1,5 |

|

2000 |

28 |

2,6 |

Table 2: Thermal Conductivity Coefficient of Earth

- Ground Installation

Rtdout(m.°C / W): Outer convection resistance of the casing pipe

hair(W / m².°C): Air convection coefficient

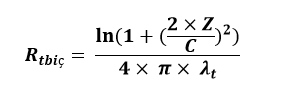

Thermal Conductivity Resistance between Flow - Return Pipes

Rtbin(m.°C / W): Thermal conductivity resistance between flow - return pipes

C (m) : Distance between the axes of flow - return pipes

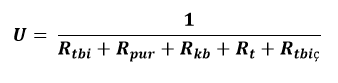

After calculating all resistance factors, the total thermal conductivity resistance value of the pre-insulated pipe system can be calculated through the formulas below:

- If under the ground:

- If above the ground:

U (W/m.˚C) : Total thermal conductivity coefficient

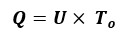

Total heat loss per metre in pre-insulated pipes:

Q=U× To

Q (W / m) : Total heat loss per metre

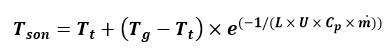

The formula below can be used to calculate the fluid temperature at the end of the line according to all calculations:

L (m) : Length of line

m (kg/sec) : Water flowrate

Cp(J / kg.°C) : Fluid specific heat [Table 3]

Tson(°C) : Fluid final temperature

|

Temperature (˚C) |

Density (kg/m3) |

Specific Heat (Kj/kg ˚C) |

|

0 |

1000 |

4210 |

|

5 |

1000 |

4204 |

|

10 |

1000 |

4193 |

|

20 |

998 |

4183 |

|

30 |

996,02 |

4179 |

|

40 |

992,06 |

4179 |

|

50 |

988,14 |

4182 |

|

60 |

983,28 |

4185 |

|

70 |

977,52 |

4191 |

|

80 |

971,82 |

4198 |

|

90 |

965,25 |

4208 |

|

100 |

957,85 |

4219 |

Table 3: Physical Specifications of Water