WHAT ARE PRE-INSULATED (GEOTHERMAL) PLASTIC PIPES?

In different countries of the world, plastic products suitable for our age have started to be used in many areas where metal materials were previously used. Today, the thermoplastics group is mostly used in pipe systems. Plastic geothermal pipes have created a usage area in home installations, industrial plants or systems with underfloor heating. When you examine the differences between plastic and metal pipes mentioned in our article below, your concern about plastic pipes will disappear.

The production of plastics is carried out by converting natural products or by synthesising the main elements. crude oil, natural gas or coal are used at the beginning of production. The basic components of plastic are carbon and hydrogen elements. As plastic materials have many properties, their usage areas are also diverse. In addition, plastics are among the materials that can be recycled.

THE HISTORY OF PVC PIPES

Polyvinyl Chloride pipes, known as PVC pipes for short, are pipe types with high worldwide recognition and high usage area. It is widely used in different household installations, agricultural processes and industrial applications with its versatile benefits.

From the transport of drinking water to sanitary installations, from irrigation pipes to the transport of liquids with different properties, PVC pipes are used in many industrial applications. PVC is known as the 3rd most produced plastic among the plastics produced worldwide

In previous years, scientists had found the PVC component while conducting their research. Among these scientists, Henri Victor Regnault, a Frenchman, and Eugen Baumann, a German scientist working in the field of chemistry, first in 1835 and then in 1872, unintentionally revealed the PVC component. However, this unintentional material did not attract the attention and interest of any of the scientists.

In 1913, the first scientist to patent PVC material was the German chemist Friedrich Heinrich August Klatte. Friedrich Heinrich August Klatte was able to document the polymerisation of vinyl chloride with the help of sunlight, which made it easier for him to obtain a patent.

Although PVC was scientifically recognised, it was not preferred by industrialists at first. The reason for this was the hard and brittle structure of PVC. Scientists worked for years to make this thermo plastic usable. After a period of 10 years, they were only able to develop the domestication process.

In 1926, Waldo Semon, owner of the BF Goodrich Company in North Carolina, USA, found that PVC could be plasticised by using other materials. With this work, PVC, whose flexibility was increased, was made usable in industry and commercial areas. An easy-to-process material emerged. In 1932, the first PVC tubes were produced in Germany. In 1935, the first PVC pipes were made in Germany. The low production and maintenance cost of PVC pipes and their versatile flexibility made them an alternative for home use before long.

After the Second World War, the production of PVC increased along with other industrial developments. The purpose of this was to create very useful products for the user derived from PVC. In order to be suitable for commercially required uses, PVC had to be mixed with plasticisers such as lubricants, heat stabilisers, fillers, phthalic acid derivatives and plasticisers for ease of processing. With these processes, materials such as CPVC (Chlorinated polyvinyl chloride), UPVC (Unplasticised polyvinyl chloride) were discovered in different parts of the world in the following years.

The chlorination process of PVC material results in CPVC material. This material is both more flexible and more resistant to high temperatures than PVC. Thanks to this feature, it has been more preferred in industry. UPVC material, which is widely used in the construction sector in many parts of the world, has a harder feature than PVC.

WHAT ARE THE COMMON USAGE AREAS OF PVC PIPES?

PVC, CPVC and UPVC pipes have become applicable in many different areas. For example, drip irrigation pipe systems, garden plastic pipes (hose), Soil-Waste-Rainwater pipes are solutions to various simple applications.

It can be easily cut with PVC pipe cutter tool and brought to the desired size. The UV resistance feature of the pipe has paved the way for its use in harsh conditions in outdoor areas. PVC pipes and derivatives have become a preferred material for many industrial, agricultural, commercial and domestic uses due to their low cost, corrosion resistance, low and simple maintenance and the advantages of serial installation.

PRE-INSULATED - GEOTHERMAL PLASTIC PIPE SYSTEMS

Pre-insulated plastic pipe systems are systems consisting of a carrier pipe, a heat-insulating material and a protective outer sheath material, which are produced in accordance with each other at the production sites. Geothermal pipe systems can typically be supplied in coils in continuous lengths or in straight continuous lengths.

In some parts of Europe, flexible pre-insulated plastic pipe applications have been used for many years in areas where energy efficiency is important in areas where district heating and cooling systems are widely preferred. High-performance insulation materials used in the pipe structure increase the efficiency of pre-insulated pipes and bring this efficiency to a sustainable position. These high-performance insulation materials minimize the heat transfer in pre-insulated plastic pipes.

In domestic and commercial construction, there are many situations that require the transport of hot or cold fluids within and between the structure and even over longer distances. Pre-insulated plastic pipes are also the best solution to prevent the transported drinking water from freezing. In addition, with this system, energy saving can be achieved by carrying hot water to long distances by embedding the pipes in a plate at the lower parts of the structures.

In many parts of the world, companies dealing with energy are looking for solutions for the transport of liquids under the best conditions. The problems to be solved are; the most favorable connection fees for homes, more serial applications to ensure that more users are served, the high durability of the pipes in addition to these advantages and the lack of need for maintenance of the system. Other problems to be solved are corrosion in pipes consisting of components such as steel/polyurethane/polyethylene, copper/polyurethane/polyethylene or copper / rockwool / polyethylene, temperature loss due to insulation material due to years of laying and humidity, and the necessity to deactivate the system for maintenance and repair, in addition to reducing high and long-term investment costs.

District heating and cooling networks for energy supply systems have always been seen as a problem in terms of cost. Continuous scientific research is being carried out to reduce the cost. Pre-insulated flexible plastic pipework has been an important development for networks with lower temperatures. Plastic geothermal pipes will be an important milestone for future network systems. As the temperature of the fluids to be transported decreases, the usage area of plastic pipe systems will increase. Until recently, the use of plastic pipes in district heating and cooling systems has remained small. Although this use remains low, the areas used have been pioneering for applications in industry. These plastic pipes have created a system that can be pulled as easily as an electric cable. Long-lasting PE-X and PB pipes were subjected to examination at the University of Leoben. In the research conducted by scientists (Eng. E. Kramer and Prof. Dr. J. Koppelmann) at the same university, oxygen induction time, tear resistance, elongation at break and internal pressure tests were carried out at temperatures of 80, 95 and 110 °C in order to reveal the life of pre-insulated pipes. The results of the tests were in favour of PB type pipes. The lifetime of this type of pipes is stated as 36 years.

WHAT IS THE TECHNICAL STRUCTURE OF PRE-INSULATED PLASTIC GEOTHERMAL PIPES?

The pre-insulated geothermal pipe assembly can be of many configurations. It can have a sheath pipe on the outside and one or more carrier pipes on the inside.

For example;

-

Two equal sized pipes suitable for hydronic pipes used for supply and return,

-

Large independent pipework to reduce the overall system diameter,

-

Pipes suitable for drinking water transport in places where the risk of freezing is high,

-

Pairs of hydronic pipes joined together by a single potable water pipework system for supply.

-

Pipes required for both heating and drinking water for dwellings.

Apart from these examples, other configurations can also be made. Heat tracing cable can be added to the system from different pipe structures.

PRE-INSULATED PLASTIC PIPE MATERIALS

In pre-insulated plastic pipe systems, most of the plastic materials are used as carrier pipes. Some of these plastic materials are HDPE, PEX, PE-RT, PE-RT, PEX-AL-PEX and PP materials.

The plastic materials in the carrier pipes have the ability to withstand different temperatures and pressures. Some of the materials in plastic pipes (e.g. PEX, PE-RT) are suitable for a permanent operating temperature of 82°C (180°F), while others (HDPE) are ideal for transporting cold or chilled water. Plastic pipe materials should never be used for steam or hot water transport at temperatures exceeding 93°C (200°F). The pressure rating of the pipe to be used during transport must be taken into consideration.

The insulation material can be applied with or without bonding. In a glued application, a bond is established between the insulation and the carrier pipe above the modulus of elasticity of the carrier pipe. In the system where the insulation material is not adhered, the carrier pipes are not connected to the insulation material. The carrier pipe can move independently of the insulation. In cases where the insulation is glued, thermal expansion and contraction are reduced in a longitudinal manner. Flexibility may be higher in products where the insulation is not glued. In general measurements, the highest thermal conductivity level in both cases is 0.30 BTU-in./h-ft2-°F (0.04 W/(m-K)).

The outer protective jacket of pre-insulated plastic pipes is made of a waterproof polyethylene material with 2-3% carbon black, which has UV protection properties. The outer jacket protects the pre-insulated plastic pipe systems from mechanical damages and moisture. It also protects the insulation material used in the pipe against both ground and other external contact. In addition, the outer jacket has a protective feature against other damages that may occur during and after the installation of the pipes.

WHAT ARE THE APPLICATION AREAS OF PRE-INSULATED GEOTHERMAL PLASTIC PIPES?

General application areas of flexible pre-insulated plastic pipes include:

-

To transport liquids from centralised heating/cooling sources, which are required to heat or cool buildings in a common way.

-

Heating systems with external boilers in remote areas (such as wood-fuelled or pallet).

-

For outdoor snow and ice melting systems with heated glycols.

-

For the transport of hot or cold liquids through or under large buildings.

-

In grass air conditioning installations.

-

For industrial applications for many different purposes.

-

Geothermal plants.

-

For transport from heat pumps that are far away.

-

For municipal water distribution systems.

-

To take precautions against freezing with temporary water supply facilities.

ADVANTAGES OF PRE-INSULATED PLASTIC PIPES

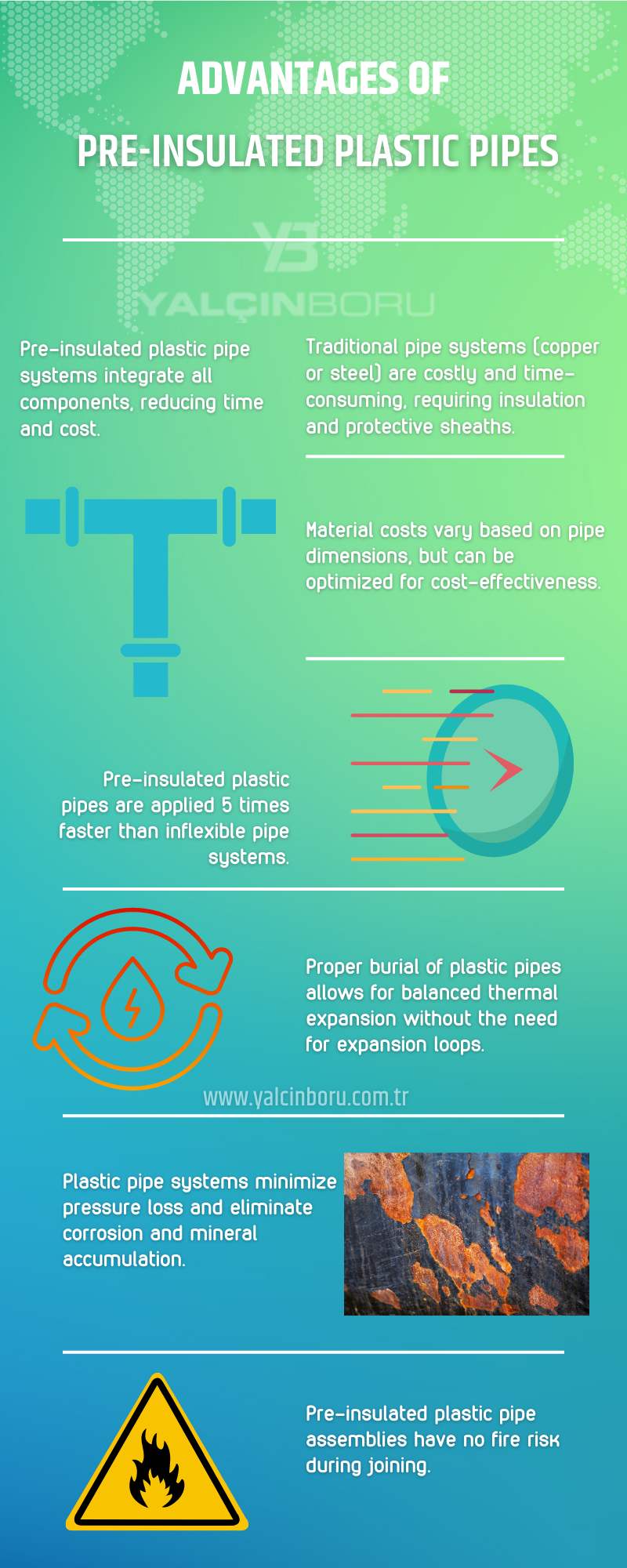

The most traditional pipe laying systems applied inside and between buildings are copper or steel pipe systems produced in straight and separate lengths, welded or soldered types, covered with insulation and having a protective sheath on the outside. In this system, which is laid by burying in the soil, an outer coating that prevents the passage of water has to be applied. This application is a costly method. In addition, the process takes a long time.

Also, if it is necessary to change the direction of the pipe in these pipe systems, fittings are needed to overcome obstacles and corners to turn the pipe in the desired direction. Since the temperature range that these systems with steel or copper pipes can withstand is wide, expansion arms and rings are needed to provide thermal expansion in a long way. During the production of these pipe systems, the mentioned assemblies have been integral parts.

In pre-insulated plastic pipe systems, all components are integrated into a single, pre-fabricated system. This system ensures consistent performance of the pipework. This application leads to a reduction in time and cost. In other pipework systems, the individual components are not pre-integrated and are applied in the field, which is not cost- and time-effective.

Pre-insulated plastic pipes can be found in one piece of 100 metres or more. This feature reduces the implementation time of the system. Initially, material costs may vary according to the dimensions of the pipes used in the installation. Cost can be reduced by selecting the most suitable materials for the dimensions of the required line. Pre-insulated plastic pipes can be applied 5 times faster than other inflexible pipe systems.

The duct cost of pre-insulated plastic pipes is also low because pre-insulated plastic pipes can be designed as inbound and outbound in a single protection sheath. While there is no need for connection in branches in plastic pipe systems, connection may generally be required in other pipe systems.

Although the cost increases in high diameter plastic pipes, the total cost is very low. If a double pipe system is used, the cost difference will be more.

Pre-insulated plastic pipe assemblies can generally be manufactured in very long continuous lengths. No joints and connections are used in these pipes. The flexibility of plastic pipes allows them to be easily bent around obstacles during laying. Again, they save time as they can become suitable for fluctuations where they are buried.

If the burial stage of the plastic pipes is done correctly and properly, the thermal expansion and contraction forces of the buried pipes are balanced longitudinally thanks to the friction with the soil. Expansion loops or arms needed in other pipe systems are not needed in pre-insulated plastic pipe systems.

In systems where the carrier pipe section is plastic, the transported liquid is transported with minimum pressure loss. There is no corrosion and mineral accumulation in plastic pipe systems. It is a long-lasting and reliable system.

In pre-insulated plastic pipe assemblies, there is no risk of fire as there is no flameless process when joining. Plastic pipe systems are also a safe application in work sites as they are lightweight.

IMPORTANCE OF DESIGN IN PRE-INSULATED GEOTHERMAL PLASTIC PIPELINES

Pre-insulated flexible plastic pipes have many advantages over steel pipes in terms of design and project arrangement. Plastic polybutylene pipes (PB) can be produced as a single piece in very long dimensions. In this way, it can be laid directly. Since it can balance its expansion by itself, there is no need for compensator and expansion curve. With this feature, 7%-10% gain can be achieved in the pipe sizes used.

Another advantage of pre-insulated polybutylene pipe systems is that friction loss and calcification do not occur during their lifetime. Polybutylene (plastic) pipe systems can operate at high fluids. Therefore, they can be used for the same load requirement with less pipe diameter size.

With the optimization and innovative designs made in the plastic piping system projects of heating and cooling lines, operating costs and investment costs are tried to be reduced to the lowest levels. With the new geothermal pipe system designs, application speed can be increased and thermal energy losses can be minimised. During optimisation, all energy consumption amounts and thermal energy losses of heating and cooling lines are examined. The structure of the buildings and seasonal differences are also important in this analysis.

The utilization of thermal networks varies according to the geographical conditions and climatic conditions where the line is located. The change in the cooling-heating network load factors that will change according to the climate affects the total cost and optimization. In cases where the energy demand does not change due to climatic conditions, the efficiency of the pipeline will be higher. If there is an excessive temperature difference between summer and winter seasons, the cost can be reduced by using lines with smaller dimensions in such places.

The design of a network to be implemented should be done in a way to serve the benefit of all users by considering not only the product but also its functionality.

WHAT ARE THE ADVANTAGES OF PLASTIC PIPELINES OVER METALLIC SYSTEMS?

When plastic geothermal pipe systems are compared with metal pipe (steel, copper, etc.) systems, it can be seen that plastic pipes have many advantages. These advantages are briefly as follows:

-

They are more resistant to corrosion than other pipes. Compared to steel and copper pipes, plastic pipes have high corrosion resistance. Polypropylene material in the structure of plastic pipes provides this. Polypropylene material helps to resist the damages of transported chemicals.

-

The service life of PP, PE and PVC plastic pipes is very long. The service life of metal pipes without special coating is short. The service life of coated metal pipes can be slightly longer.

-

Plastic pipes are lighter than metal pipes. Due to this feature, it is easy to transport and install. Therefore, the cost is low. Lifting tools are not used during the laying of plastic pipes. Since metal pipes are heavy, lifting apparatus is needed.

-

While metal pipes have no flexibility, plastic pipes are flexible and can be bent. When plastic pipes are laid under the ground, they transfer point loads and stresses to the ground by means of deformation. No additional load is placed on the pipe.

-

Plastic pipes show high resistance against substances with chemical properties. This type of pipes can be used easily in industrial plant constructions. Metal pipes, on the other hand, need special coatings to protect them from the damages of chemicals, which causes an increase in cost. metal pipes without special coatings may be vulnerable to chemicals.

-

Plastic pipes have high abrasion resistance. This feature makes plastic pipes more durable. The friction between the inner parts of the pipe and the transported material causes mechanical wear. This wear is more common in metal pipes.

-

Plastic pipes, for example thermoplastics, are fully recyclable products. It has a sustainable feature. It contributes to raw material and energy resources due to its recyclability. It is economical as it does not require high energy input to be converted into energy.

-

A lot of energy is required for the production and processing of metal pipes. They are not sustainable due to this negative aspect. Metal pipes can also be recycled.

-

During the assembly of plastic pipes, no open flame process is performed during welding works. There is no risk of fire. Connection technologies are also used in the best way in plastic pipe systems. These pipes are easily joined by heating the pipe and fitting with the help of suitable tools. When joining, melting occurs in the same way at every point of the plastic pipe to be welded. In this way, a permanent and secure connection is formed. In metal pipes, open flame may occur during the process. This poses a fire risk.

-

Raw material costs of pre-insulated plastic pipes are lower. While the production cost is high in metal pipes, the production cost is also cheaper since the raw material is cheaper in plastic pipe systems. Welding costs are also more favourable than metal pipes.

IS IT NECESSARY TO INSULATE PLASTIC HEATING PIPES?

If plastic pipes are to be used in hot and cold water transport or central-local heating and cooling, insulation is required to prevent heat transfer. Insulation may also be mandatory against the risk of freezing. The insulation standard of plastic pipes should be the same as metal pipes.

IS IT POSSIBLE TO INSULATE PLASTIC HOT WATER PIPES?

The thermal conductivity of plastic pipes is lower than metal pipes. For this reason, it can be thought as if insulation is not done. But this thought is wrong. If plastic pipes are well laid, installed and assembled carefully and insulated ones are also selected, heat loss rates can be reduced up to 25%.

DOES PLASTIC PIPES FREEZE?

Almost all pipes, including copper and steel, can freeze. If freezing occurs, breakage may also occur. The most vulnerable pipes to breakage are copper pipes. But the advantage of plastic pipes is that there is little risk of explosion even in case of freezing.

CAN PVC PIPES BE USED FOR HEATING?

PVC pipes are more preferred for heating and cooling than metals because the material of the pipes is very good in insulation. Metal pipes do not retain heat as well as plastic pipes.

UP TO WHAT TEMPERATURE DOES PLASTIC PIPE WITHSTAND?

The maximum recommended temperature for plastic (PVC) pressure pipe is 140°F. Plastic pipes become flexible at higher temperatures and stiffer at lower temperatures.

WHAT SHOULD BE CONSIDERED WHEN CHOOSING PRE-INSULATED PLASTIC PIPES?

When choosing the right pipe, we need to pay attention to the factors listed below. These factors are briefly as follows:

-

How much pressure the planned pipework must withstand,

-

What is the highest temperature of the fluid to be transported by the plastic pipe,

-

Whether the connection will be made during the installation and assembly phase,

-

What kind of chemicals will be transported with plastic pipes,

-

The permanent loads to which the pipe system will be subjected,

-

Whether thermal expansion and contraction will be important in the pipe system to be installed.

WHAT ARE THE POINTS TO BE CONSIDERED IN THE INSTALLATION OF PLASTIC GEOTHERMAL PIPES?

The properties of each plastic pipe vary according to each other. Accordingly, the precautions to be taken during installation are different. In general, the points to be considered during the installation of polypropylene pipe systems are as follows:

-

Firstly, the pipes should be checked for damage.

-

Plastic geothermal pipes should not be removed from their storage cases to prevent damage until the process starts. With this application, the plastic pipe is protected against scratches and contamination.

-

Attention should be paid to weather conditions during the installation of PP pipes. There is a risk of damage to plastic pipes under very low-temperature conditions.

-

If the pipes are to be stacked, a flat place should be selected against breakage and bending and heavy loads should not be left on it.

ARE PRE-INSULATED PLASTIC PIPES HARMFUL TO HEALTH?

Pre-insulated plastic pipes produced in high quality are unlikely to pose a health risk. Thanks to the standards established in the production of plastic pipes, safe products can be obtained in terms of health. It is important to choose pre-heat insulated plastic pipes in accordance with their intended use. For example, pipes to be used in the industrial field may need to be produced from materials resistant to the chemical effect to which they will be exposed. Pre-heat insulated pipes to be used in city network or residences are produced from suitable materials.

If the fluids transported by pre-insulated plastic pipes reach high temperatures, some substances may be released from the plastic material. However, today, plastic pipes used in the transport of food and drinking water are produced in a way that does not pose a risk to human health.

Today, PVC material is used in the production of pre-heat insulated plastic pipes. CPVC material is obtained by subjecting PVC to chlorination process. CPVC has a more flexible structure and offers the possibility of use at higher temperatures. As it is known, chlorine is used for disinfectant purposes in certain proportions in city network water and drinking water. The components and the amount of chlorine used in CPVC and PVC raw materials are within the standards set by the World Health Organisation and do not pose a risk to human health. Heavy metals such as tin, barium and zinc, which pose a risk to human health and the environment, are not used as components in the production of PVC pipes.

As a result, pre-insulated plastic pipes are very safe products in terms of health. Pre-heat insulated plastic pipes should be determined according to the sector to be used and the properties of the fluids to be transported.

DO PRE-INSULATED PLASTIC PIPES CAUSE CANCER?

There is no scientific study that pre-heat insulated plastic pipes cause cancer. After the stages that PVC raw material goes through in the processing process, products are obtained in line with the criteria determined by the World Health Organisation.

PVC and derivative pipes used in pre-insulated plastic pipes continue the necessary processes until they are purified from the chemicals they are subjected to during the production phase. In this way, the product obtained does not pose a health risk as long as it is used under the specified conditions.

Therefore, there is no risk of cancer in pre-insulated pipes. However, pre-thermally insulated plastic pipes should be used to transport fluids suitable for the properties of these pipes.

It should not be forgotten that PVC and derivative materials, which are widely preferred in the world, are safely used as raw materials in the manufacture of many products in the medical field.

DO PRE-INSULATED PLASTIC PIPES CAUSE ENVIRONMENTAL POLLUTION?

Pre-insulated plastic pipes, which are highly preferred for their durability and long life, do not cause environmental pollution. It is more advantageous than metal-containing pipes in terms of recycling. Pre-insulated plastic pipes can be completely recycled. In this way, it is a very successful product in terms of sustainability.

It is very wrong to leave pre-heat insulated pipes that have completed their service life to rot in nature. Such a situation is of course undesirable. By raising awareness of businesses and having the right waste management policies, both nature is protected and it becomes possible to bring waste into the economy.

WHAT ENVIRONMENTAL FACTORS ARE GEOTHERMAL PLASTIC PIPES RESISTANT TO?

Pre-insulated plastic pipes, which are highly preferred for the safe transportation of various fluids and maintaining thermal insulation, have high durability against various environmental factors.

First of all, it is possible to use pre-heat insulated pipes in high and low-temperature conditions. It is resistant to freezing at low temperatures. At the same time, it is resistant to rapid temperature changes. It can also be used safely in heating and cooling systems.

Pre-heat insulated plastic pipes are resistant to chemical effects. It is resistant to both the leakage of the transported fluid and the leakage of any chemical substance from the outside into the pipe.

PVC pipes are affected by sun rays, but PVC pipes protected against UV rays can be produced if needed.

PVC pipes, which are very resistant to water and moisture, can be used in all climatic conditions.

Pre-insulated steel pipes are resistant to various impacts, cracking and breaking.

Compared to metal-containing pipes, it is more resistant to corrosion caused by environmental factors.

Contents

WHhat Are The Common Usage Areas Of PVC Pipes?

Pre-Insulated Plastic Pipe Systems

What Is The Technical Structure Of Pre-Insulated Plastic Pipe?

Pre-Insulated Plastic Pipe Materials

What Are The Application Areas Of Pre-Insulated Plastic Pipes?

Advantages Of Pre-Insulated Plastic Pipes

Importance Of Design In Pre-Insulated Plastic Pipelines

What Are The Advantages Of Plastic Pipelines Over Metallic Systems?

Is It Necessary To Insulate Plastic Heating Pipes?

Is It Possible To Insulate Plastic Hot Water Pipes?

Can PVC Pipes Be Used For Heating?

Up To What Temperature Does Plastic Pipe Withstand?

What Should Be Considered When Choosing Pre-Insulated Plastic Pipes?

What Are The Points To Be Considered In The Installation Of Plastic Pipes?

Are Pre-Insulated Plastic Pipes Harmful To Health?

Do Pre-Insulated Plastic Pipes Cause Cancer?

Do Pre-Insulated Plastic Pipes Cause Enviromental Pollution?

What environmental factors are geothermal plastic pipes resistant to?